Sanitary Emulsifying Pump Single-stage Multi-layer YUY-R

- Specifications

- 0.5T-13T,0.37KW-5.5KW

- Material

- SUS304,SUS316L

- Speed

- 960-1400(rpm)

Product introduce

Santiary Pipeline high speed shearing emulsifier is of functional to smash, to refine and to mix/disperse and to emulsify the suspensions, aerosols and emulsions, efficiently, quickly and evenly.

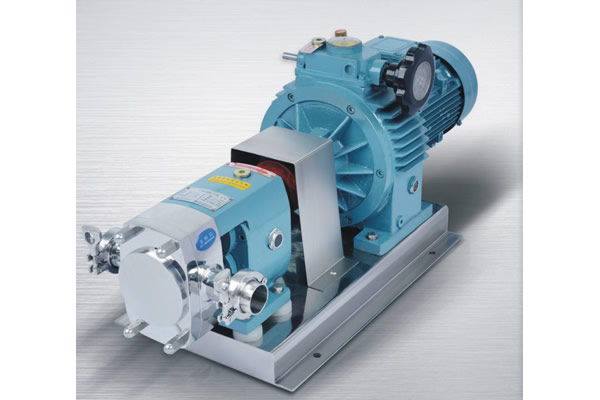

YUY-R series In - Line high shear homogeneous pump is used in online sustained or cyclic processing elaborate materials in the narrow chamber, it is with 1 - 3 groups of coupling double rotators and stators The materials are sheared by the equal probability when through the work chamber and the granule size reduced. upgrade the effect. On - line eliminating the quantity difference between different batches, make sue the constant quality. Stator and rotator module combination make it suitable for different operating condition requirement Online measur - ement of mixing design makes the intensive production come true it has short distance low - lift transport function.

Pipeline type single - stage emulsion pump is efficient, rapid, uniform to a phase or multiple phases (liquid, solid, gas) into another immiscible continuous phase (usually liquid) process equipment, But in typically each phase is immiscible. When the external energy input, a two material reorganization to become homogeneous. Pipeline type single -stage emulsion pump with high speed rotation of the rotor generated by high tangential velocity and high frequency mechanical effect brought about by strong momentum, so that materials in the stator rotor, narrow gap by the strong mechanical and hydraulic shear, centrifugal extrusion, liquid layer friction, collisions and turbulence integrated action, forming a suspension (solid / emulsion (liquid), liquid / liquid)and foam (gas /liquid). Horizontal pipeline type single - stage emulsion pump so that the insoluble solid phase, liquid Phase, gas rase in the corresponding ripe technology and proper amount of additive joint action falls, Instant fine dispersed emulsion, emulsion pump through frequency move in circles, finally get a stable high-quality products.

YUY-R series is a single-stage multi-layer and three-stage multi-layer sanitary shear homogeneous emulsification pump specially designed by our company for customers.

The high tangential speed generated by the high-speed rotation of the rotor and the strong kinetic energy brought by the high-frequency mechanical effect make the material flow in the narrow space between the stator and the rotor.

The gap is subjected to comprehensive effects such as strong mechanical and hydraulic shearing, centrifugal extrusion, liquid layer friction, collision tearing and turbulent flow.

Instantly fully and effectively mix and homogeneously emulsify multi-phase (solid, liquid, gas) media.

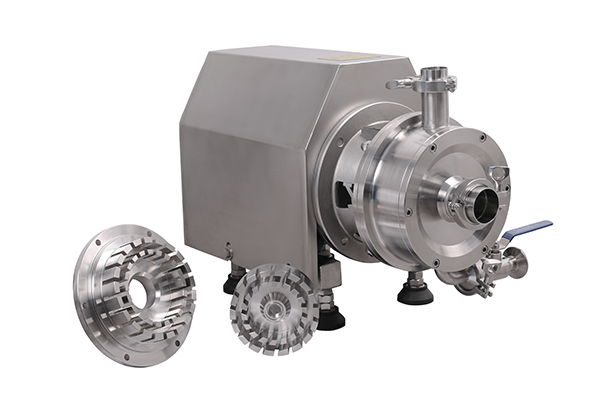

The mainstream design of the stator-rotor structure is the stator-rotor mesh type and the blade mesh type. The cutting head can be set as single circle or multiple ring, single-stage or multi-stage, and various stators and rotors can be easily disassembled and combined according to needs to obtain optimized Dispersion and mixing effects.

Application of Single-Stage Multi-Layer Emulsifying Pump in the Preparation Process of Suspensions

During the preparation process of suspensions, it is necessary to avoid problems such as precipitation and agglomeration of the main materials, and to ensure uniform sediment concentration after discharge, so as not to affect the batch quality of the finished product.

In the processing of large quantities of materials, conventional shear in-tank processing has dead angles in the dispersion system of suspensions, making it difficult to control the feeding ratio. To address such dispersion processes, Yuan En adopts a more efficient and improved solution: using the YUY En single-stage multi-layer emulsifying pump for external circulation online shear of materials, which can effectively avoid dead angles in processing, fully disperse the main materials uniformly, and ensure the uniformity of the materials.

Based on actual case data, it can be observed that with the use of the single-stage multi-layer emulsifying pump, the probability of shear for 100L of material is nearly 100%, and after two cycles, uniform dispersion can be achieved, significantly improving the efficiency of mixing and dispersion in the tank. Post-shear observation shows no agglomerated fine particles, and the liquid exhibits viscosity. The main drug is uniformly dispersed, with a particle size of around 5-10um, meeting the process requirements.

|

|

|

| Double-layer stator and rotor meshing type | Multi-layer stator and rotor meshing type | Single-layer blade mesh type |

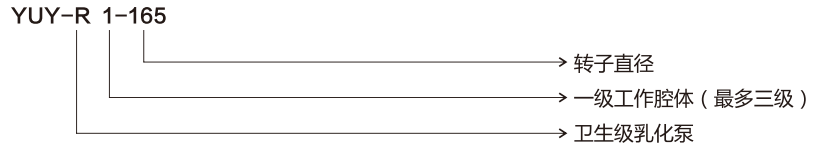

Model meaning

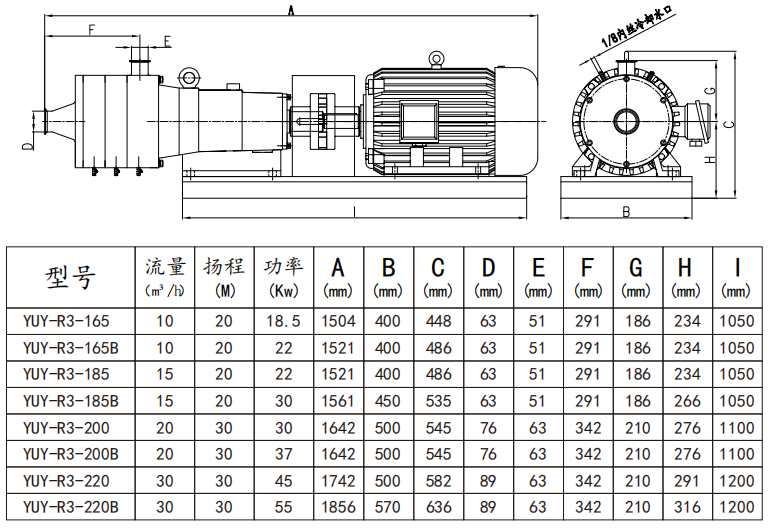

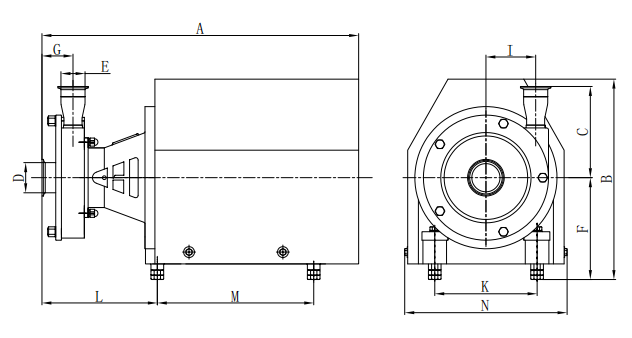

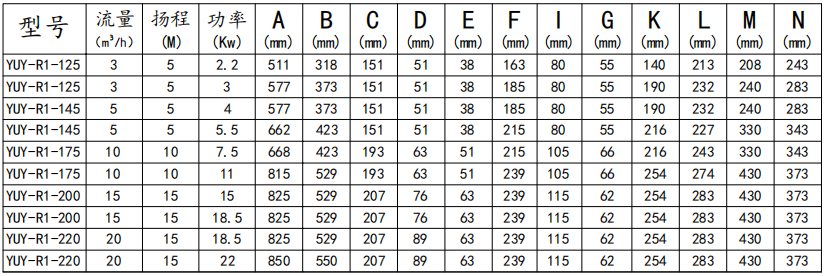

Technical Parameters

Note

1. The above installation dimensions are for reference only.

2. The processing capacity in the table refers to the data measured when the medium is water.

3. If the medium has viscosity or solid content, high temperature, high pressure, flammable, explosive, corrosion, etc., please provide detailed data.

Technical Parameters